Reciprocating Friction Tester warehouse|high frequency friction tester : custom The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece. The acquisition of anolog signals is done . WEBSiga o clássico entre Benfica e FC Porto AO MINUTO. 29 set 2023 20:00. I Liga. Benfica. slb. Porto. fcp. primeira-liga. Benfica - FC Porto.

{plog:ftitle_list}

List of ExtraTorrent proxies. https://extratorrents.cd very fast; https://etmirror.com fast; https://etproxy.com offline; https://extratorrentonline.com slow; https://extra.cd fast; .

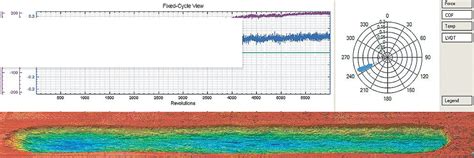

Using various sensors it measures friction, wear, and adhesion of any reciprocating test setup with ease. The patented in-line 3D profilometer automatically measures topography change during the test. The module . Measurement and control system design and texture anti-friction test of reciprocating friction tester based on compliant mechanism November 2021 DOI: 10.1117/12.2612004 The vertical load, friction ball diameter and reciprocating movement frequency (friction speed) are selected as the experiment factors. The cutting tools was installed in the special designed fixture on a reciprocating movement wear test machine. The wear depth increases with the increase in the Z-load, ball diameter and frequency. The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece. The acquisition of anolog signals is done .

The machine may be used to evaluate the friction and/or fatigue performance of rubber-like materials A compact reciprocating friction and wear tester which has been used extensively in the friction testing of elastomeric materials is described in this paper. Fig 1 is an overall view of the machine showing the basic bench type mounting and . The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it. Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece.Polymer Testing 9 (1990) 195-211 Reciprocating Sliding Friction and Wear Test Apparatus S. M. H. Benabdallah Department of Mechanical Engineering, Ecole Polytechnique de Montrral, PO Box 6079, Station 'A', Montreal, Quebec, Canada, H3C 3A7 (Received 4 November 1989; accepted 2 December 1989) ABSTRACT As the friction and wear properties of polymers are .Historical/Traditional Test Geometry. The classic work of Thurston 1, Martens 2, Stribeck 3 and Hersey 4 were done using a journal-bearing geometry, which possesses all of the above requirements (Figure 3). An instrumented journal-bearing test allows for evaluation of the friction over a range of relative velocities and/or loads.

Featuring a patented test principle, the SRV®5 tribometer allows for high-precision friction and wear tests of lubricants, materials, coatings and components. The SRV®5 tribometer offers a wide range of practice-relevant test concepts, even in its standard configuration with oscillation.Friction and wear study of sliding surfaces plays a prominent role in the development of materials for various applications. The development of a low-cost multipurpose reciprocating tribometer at constant sliding speed to study the tribological properties of a material under dry, wet and high temperature conditions is presented in this paper. The tribometer has the ability of . The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. There are many factors exerting influence on it.TRB³ pin-on-disk tribometer is the industry standard for friction, wear, and lubrictaion measurement. Learn more about its features and specifications. . reciprocating), contact modes, speed, lubrication, materials, high temperature, humidity, etc. . . together with friction force and other testing data in real time. Calibrate TRB³ with .

The test rig can evaluate the performance of different surface treatments such as hardening, nitriding, and electroplating.This can provide valuable information on how different surface treatments can be used to improve the performance of mechanical components.. Some reciprocating sliding friction and wear test rig can also be used to study the effect of .output the root-mean-square friction force to a strip-chart-recorder or to a computerized data acquisition system.5 The method of sensing and recording friction force during the test shall be described in the testing report. 6.5.2 Test Duration—In this test method, test duration is specified in seconds. To compute the sliding distance in metres The initial decrease in friction in the reciprocating tests on 316L stainless steel, reducing ploughing friction through smoothing of surface asperities, was also observed in 10-cycle nano-scratch tests at 30 mN with a 3.7 μm radius diamond [9] (data converted to friction coefficient in Fig. 9) and in 1 N tests on copper with a 100 μm radius .

To facilitate the in-depth study of the tribological behavior of texture friction pairs in the process of reciprocating friction. The micro-displacement deformation output model of compliant mechanism is deduced using a new method for indirectly measuring friction coefficient through micro-deformation of double parallel four-bar compliant mechanism. Then, the whole structure .

linear wear friction testing

2.1 Pin-on-Disk Tribometer. The most commonly used configuration for testing materials is the pin-on-disk method in either rotating or linear-reciprocating modes. The corresponding ASTM standards, G99 [] and G133 [], include the measurement of friction coefficient as well as wear rate of the sample and the static partner.The pin-on-disk setup has .The analysis of friction and wear properties of materials at elevated temperatures has become increasingly important, especially for the development and quality control of combustion engine and power plant constituent parts.To meet the resulting need for quantitative data at elevated thermal conditions Anton Paar has extended its range of pin-on-disk tribometers with a .Rtec SRV Tester studies friction and wear of lubricants and grease. ASTM, DIN, ISO compliant, with wide test range. Stroke control from 5um . Dedicated SRV tester for reciprocating friction and wear analysis. SRV Test on Multi Function Tribometer MFT-5000. SRV test on the MFT-5000 allows several other friction, tribology, wear tests on the .

Based on the bench test, a system is developed for measuring the variation of the friction force between upper and nether test-piece and the real-time curve is made to provide the foundation for the further investigation. The variation of friction force between upper test specimen and nether test specimen is very complicated on the reciprocating wear tester. .Introduction of Electric Friction Decolorization Tester Electric Friction Decolorization Tester Using white cotton which is dry or wet rolled the surface of abrasive hammer in this machine to test the dyeing fabric and dyeing leather. and then reciprocating friction the specimens 10 times within 10 seconds, can be assessed the grade of dyeing .The machine is the most standard type to measure fiber and printed matter for fastness against friction. Number of samples: 6 pcs: Load: 200 , 500gf: Rubbing finger: 20×20㎜ , R45㎜ Stroke: 120㎜ Reciprocating frequency: 30cpm: Counter: 5-digit pre-set counter: Ref. standard: JIS K 5701 , JIS P 8136 , JIS L 0849: Power supply: AC100V .Lubricants play a vital role in machine life and performance, reducing friction and wear and preventing component failure. Performance-enhancing additives are a vital part of today’s modern .

In brief, an in-house-built tribometer was used and operated in ball-on-flat linear reciprocating test conditions with a stroke of ~1 mm at a reversing frequency of ~1 Hz. Plane polished titanium alloy (Ti6Al4V) samples were used along with 10 mm diameter counterbodies (hardened 100Cr6 steel or Si 3 N 4 ceramic) in dry or oil-lubricated . The aim of the present work was to investigate the reciprocating friction and wear behavior of MCMBs-derived reaction-formed SiC submitted to dry sliding tests against bearing steel ball under different loads, in order to determine the effects that the microstructural features and properties can have on friction and wear behavior, as well as to . Friction and electrical contact resistance in reciprocating nano-scale wear testing of metallic materials Ben D. Beake 1 ,* , Adrian J. Harris 1 , Tomasz W. Liskiewicz 2 , Jérémie Wagner 3 , Sam J.Product Product Download If you want to download this product information Please click here Used for the determination of the abrasion resistance of the test piece. Friction hammer reciprocating movement, specimen clamping on the test bench by the weight increase generated frictional resistance, During the test by automatic counting counter and display, the .

Aiming at the reciprocating motion existing in the space rolling bearing, the wear characteristics of the reciprocating friction of MoS2 were studied. The friction simulation between Fe–Ni–Cr substrate and MoS2 is simulated by mixing multiple potential functions. and came to the following conclusions: . such as gas and magnetic suspension .

linear friction tribometer test

high frequency reciprocating rig

high frequency friction tester

A casa das novidades faça sua aposta no cassino online. Rapidez e agilidade, do depósito ao saque!

Reciprocating Friction Tester warehouse|high frequency friction tester